What is Pipe Beveling & Why is it Important to Get it Right?

- George Ficken

- Nov 6, 2023

- 2 min read

Pipe beveling is a crucial machining process used in various industries to prepare the edges of pipes or tubes before joining them together through welding or other methods. The beveling process involves cutting or shaping the end of a pipe at a specific angle, creating a sloped surface or a chamfer. The primary purpose of pipe beveling is to facilitate a smooth and secure weld joint, ensuring that the two pipe ends fit together precisely, promoting efficient welding and minimizing the risk of defects or leaks in the connection.

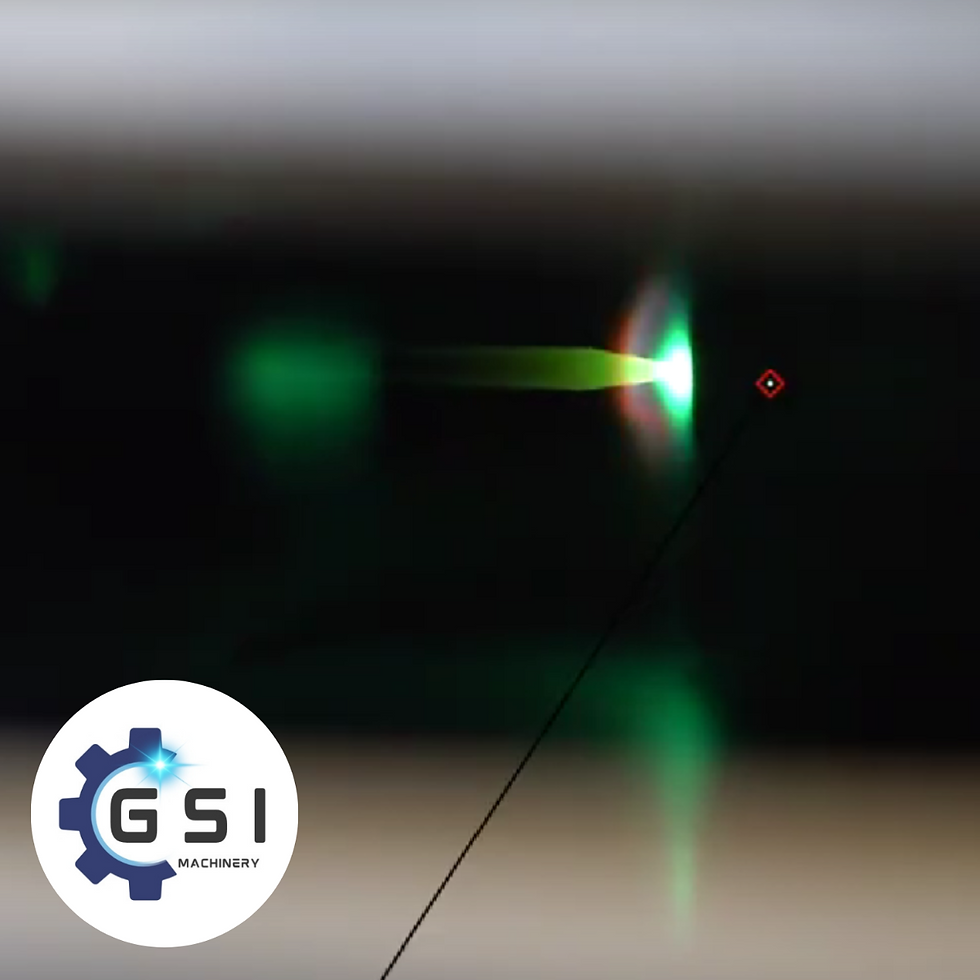

There are several types of pipe beveling methods, each suited to specific applications and materials. One common approach is mechanical beveling, where specialized machines use cutting tools to shape the pipe end accurately. This method is widely used for pipes of various sizes and materials. Another method is flame beveling, which employs a torch to heat the pipe's edge, allowing for a beveled shape through controlled heating and material removal. Additionally, there are automated and manual beveling techniques, depending on the level of precision required and the complexity of the pipe's end configuration.

Pipe beveling plays a vital role in various industries, such as oil and gas, construction, and shipbuilding. In welding operations, proper beveling ensures a larger surface area for the weld bead, resulting in stronger and more reliable connections. It also helps to control the weld penetration depth and reduces the risk of defects such as lack of fusion. Moreover, beveled pipe ends promote smooth fluid flow within the pipeline, minimizing turbulence and pressure drops, which is crucial in maintaining efficient fluid transportation in industrial processes.

In conclusion, pipe beveling is an essential process that prepares pipe ends for welding or joining, ensuring precise fitment and strong connections. Its contribution to achieving reliable and efficient welded joints cannot be overstated. Whether in critical industries like energy or infrastructure, or in everyday applications, proper pipe beveling enhances the performance and longevity of pipelines and helps maintain the integrity of various industrial systems.

GSI Machinery rents, sells and provides training for Esco Tool MillHog brand pipe and tube beveling machines. If you are interested in improving your beveling consistency and throughout please reach out to learn more.