3 Things to Look for When Considering an Automated Pipe Welding Machine

- George Ficken

- Jan 6

- 3 min read

There is a lot of buzz going on right now in the world of welding automation and the pipe welding niche is no exception. When you start to look around at options you will hear a lot of buzz words like Ai for example a word that gets tossed around alot these days. But it is important to understand what to look for in these machines so you don't get misguided into thinking that a machine is something that is it not. Here are our top 3 things to consider when buying an automated pipe welding machine for your shop.

Software

Rotoweld makes all of their software in-house with full time software engineers so their Ai software is completely proprietary. Also this means that your software version will be supported for the life of the machine, since Rotoweld designed the software they can continue to support it in the future so you will not find your software has become obsolete or not supported. It also means that you will get full tech support over the internet, Rotoweld techs in Montreal can remote into your machine and add programming, update software or completely flash software if needed. We do not charge any annual licensing fees with our software, you buy the software and you own it outright.

The software data collection software is called ProData Log and it will record a video of each weld made, record data on any fit-up errors it detects and record any recommended adjustments you should make either to the welding program or the fitup. All this data automatically syncs to the cloud which you can access on your phone or computer. Attached are some screen shots of some of the data you can see on ProData Log.

Build Quality

Rotoweld is 100% made in Montreal, Canada with parts sourced from Japan and Germany primarily. Rotoweld is a family owned and operated business and they have been building these machines for 35 years. Their robotic arm is made in-house so it is not another company's robotic arm and so are the welding positioners. The positioners are direct drive electric positioners so that they do not develop slop over time like many gear-driven positioners do, which will cause issues for the automated welding software. Service is taken care of directly by Rotoweld and sometimes with local assistance from us if needed so you have both local support and 24/7 access to the factory direct techs as well.

Welding Process

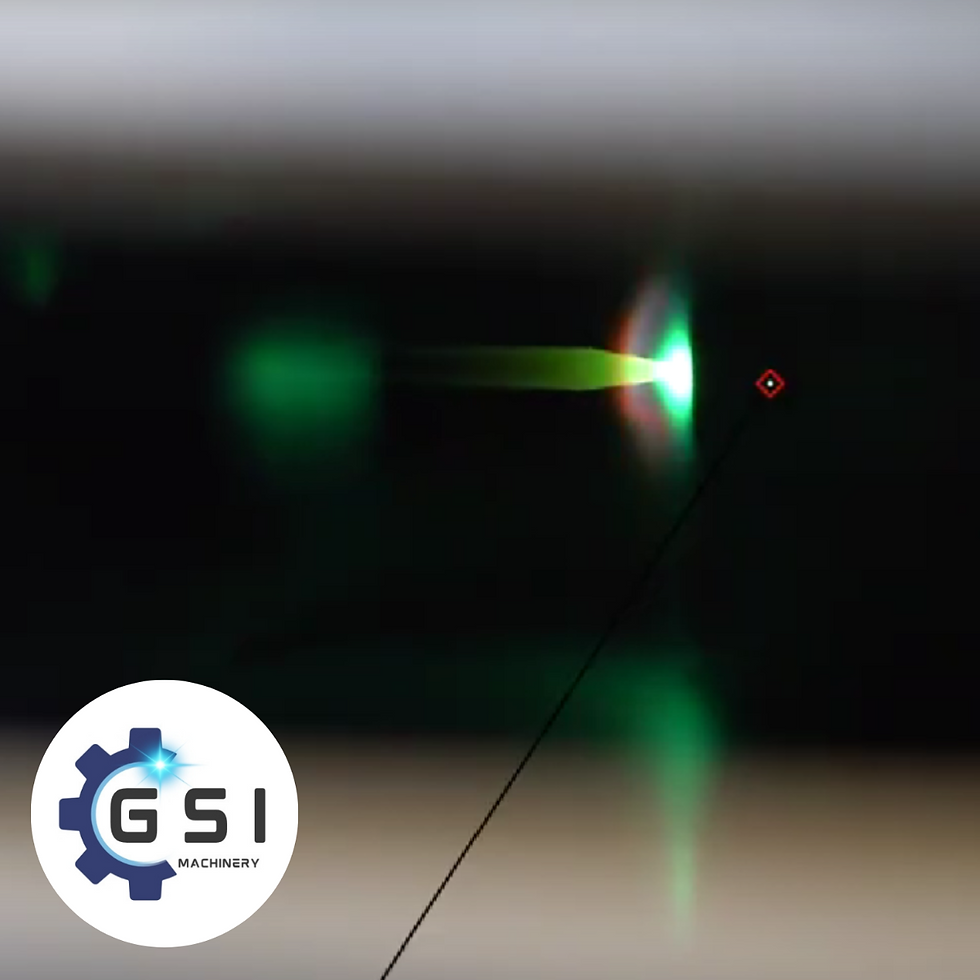

Something I forgot to mention on our call is that we use a 2 torch system you will notice. This is so that we can use the Lincoln STT process for our root pass welding. This allows us to do open root welding with roughly a 3/32" - 1/8" gap allowing us to move very fast (we weld at about 1 min per 1in of nominal pipe OD, so we can weld a 6in sched 40 pipe in 6 min root to cap with no operator input needed) with a very well controlled puddle - giving us excellent penetration. The machine automatically lowers the welding torch into a 45 degree position which after 35 years of research Rotoweld has found that torch angle allows us to move the fastest with the best penetration. It is important that the machine automatically sets this torch angle as this can be a point of error if the operator is moving the torch into position manually for each weld.

Rotoweld - PerfectPass IQ This is a video of our Ai software making welds and what the operator will see

Rotoweld 3.0 - 6" SCH 40 - Welding Time This is a time trial from one of our customers

Rotoweld 3.0 at Way Engineering This is a video from one of our customers in Houston that gives you an idea of the different layout and how the machine fits into a production environment.

If you would like to see a demo of our automate pipe welding solution the Rotoweld, reach out to schedule a demo at our Houston "Center for Automation Excellence" in Texas today!