Why is Ceriated Tungsten a Good Choice for Orbital Welding Applications?

- George Ficken

- Oct 2, 2025

- 2 min read

Updated: Oct 10, 2025

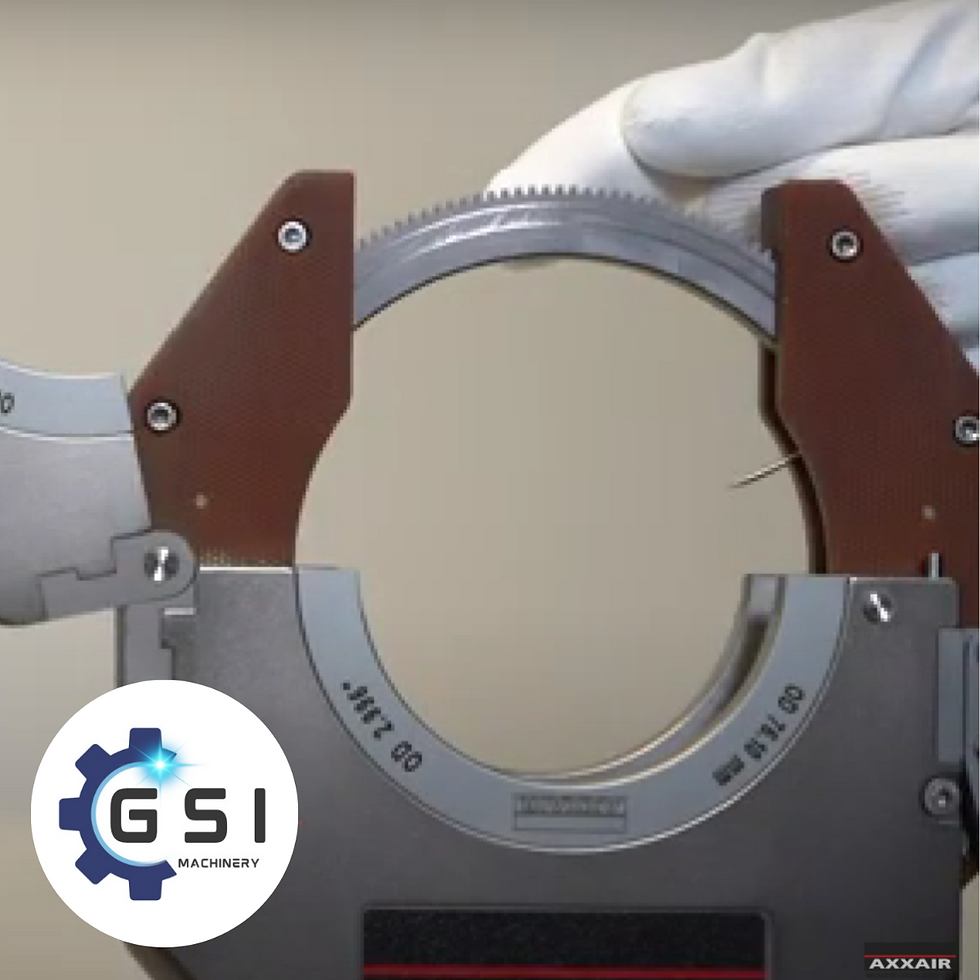

Orbital welding is a highly precise, automated welding process commonly used in industries like aerospace, semiconductor, pharmaceutical, and nuclear power — where clean, repeatable, and high-integrity welds are essential. In these tightly controlled environments, every component of the welding process matters — especially the choice of tungsten electrode.

One of the most popular electrode types in orbital welding is 2% ceriated tungsten (AWS classification: EWCe-2). But what makes this type of tungsten superior for orbital applications? Let’s explore the key reasons.

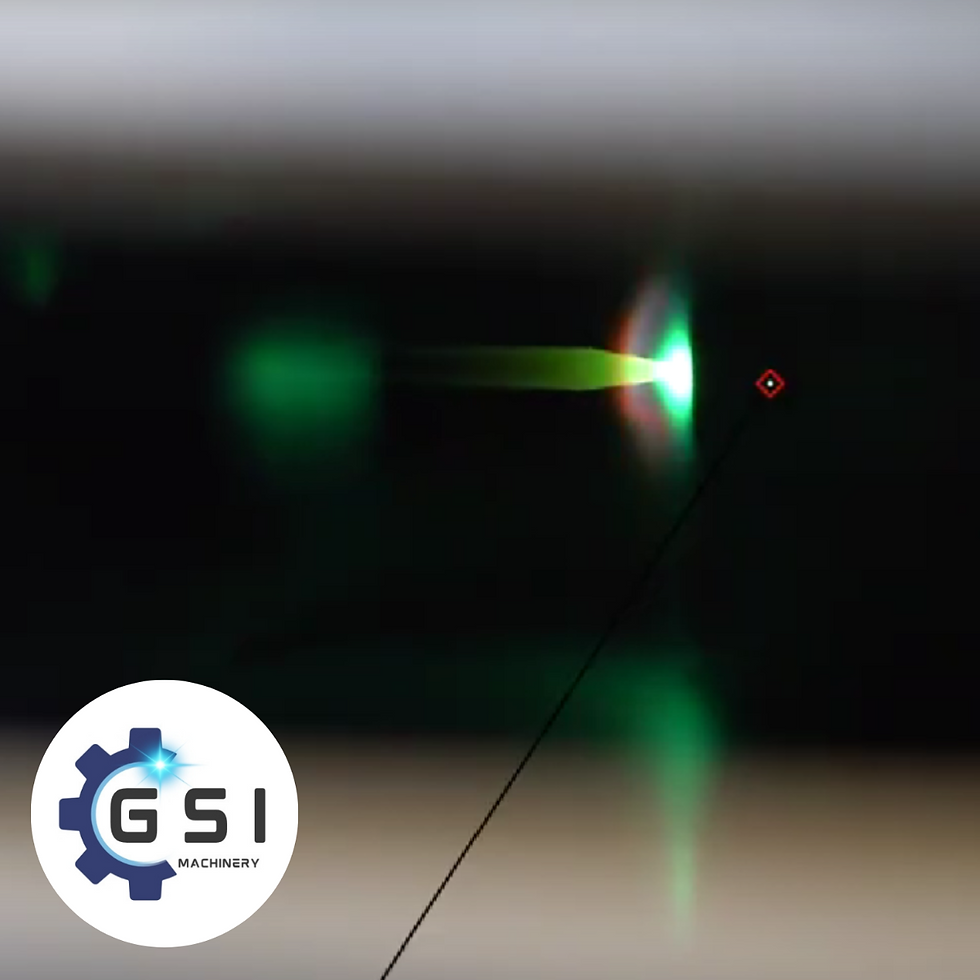

1. Excellent Arc Starting Characteristics

Orbital welding systems often rely on reliable and repeatable arc starts, especially in automated and high-volume environments. 2% ceriated tungsten provides very low starting voltages and stable arc initiation, making it ideal for orbital weld heads where consistency is critical.

✔️ Easy arc ignition

✔️ Less wear on high-frequency start systems

✔️ Improved arc control in low-amperage ranges

2. Superior Performance at Low Amperage

Orbital welding often involves thin-wall tubing and materials like stainless steel or titanium, which require precise control at low to moderate amperage ranges (typically 5–200 amps). Ceriated tungsten excels in this range, maintaining arc stability without overheating or balling up.

🔧 Ideal for autogenous welds (no filler)

🔧 Better control over heat input, minimizing distortion

3. Non-Radioactive and Safer to Handle

A common alternative to ceriated tungsten is thoriated tungsten (EWTh-2), which has excellent arc properties but contains radioactive thorium. In high-volume or enclosed orbital setups, health and safety concerns become important.

⚠️ Thorium poses a radiation hazard when grinding electrodes

✅ Ceriated tungsten is non-radioactive, making it safer for welders and technicians

✅ No special ventilation or disposal requirements

4. Longer Electrode Life and Durability

In an automated process like orbital welding, downtime for changing electrodes can be costly. 2% ceriated tungsten offers good wear resistance, particularly under the steady-state conditions typical of orbital welding.

⏳ Longer life compared to pure or zirconiated tungsten

🧼 Maintains a sharp point longer, contributing to cleaner, more precise welds

5. Versatility Across Materials

While optimized for DC welding (Direct Current), 2% ceriated tungsten performs well across a range of materials:

Stainless steel (most common in orbital applications)

Inconel

Titanium

Nickel alloys

It can also be used for AC welding in some cases, although it’s not the best choice for aluminum.

Summary: The Ideal Electrode for Precision Welding

Feature | 2% Ceriated Tungsten (EWCe-2) |

Arc Starting | Excellent |

Low-Amperage Performance | Outstanding |

Safety | Non-radioactive |

Electrode Life | Long-lasting |

Ideal Applications | Stainless steel, titanium, orbital tube welding |

For orbital welding, where precision, consistency, and safety are paramount, 2% ceriated tungsten strikes the perfect balance between performance and practicality. It’s no surprise that it has become the electrode of choice for many orbital welding operations around the world.

Interested in optimizing your orbital welding setup? Reach out to GSI Machinery for all of your orbital tube welding needs for rentals, repairs, training and sales. GSI offers expert support and fast, well-maintained rental equipment ready for your most critical projects - call us 24/7!