Orbital Welding: Closed vs Open Weld Heads

- George Ficken

- Aug 26, 2024

- 3 min read

Updated: Sep 19, 2024

With many options on the market today for orbital welding equipment, you may be wondering what are the differences between open and closed orbital welding heads and when do I use one over the other? This post should help clarify the different uses for both closed and open orbital welding heads and when you should consider using one over the other.

Closed Orbital Welding Heads Overview

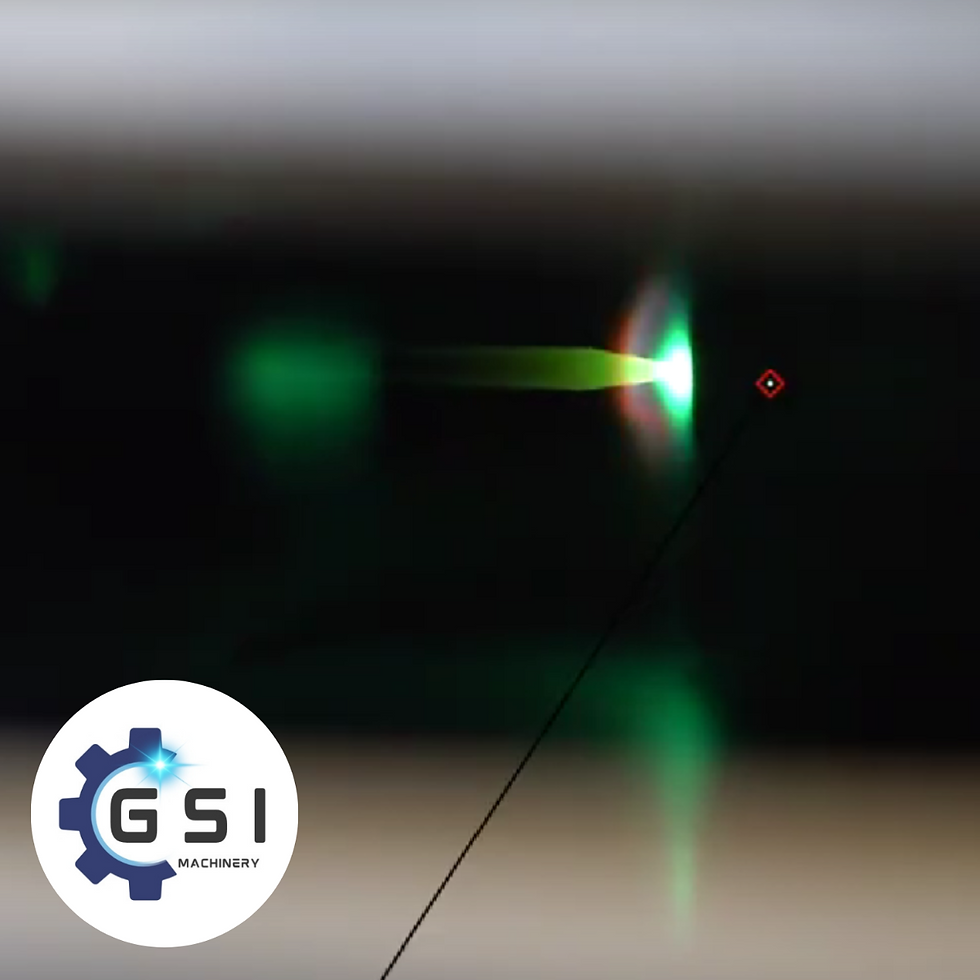

Closed orbital welding heads are used for autogenous, fusion orbital welding applications that do not require a wire filler. These applications typically involve tube or thin wall pipe from .120" wall and thinner. GSI recommends the Axxair "SATFX" line of closed fusion orbital welding heads for such applications. If you can get away with fusion welding, we recommend it over a wire-fed application because it is simpler to program, repeat consistently, has faster cycle times and saves money on consumables such as wire. Not only is it faster, the closed orbital welding head helps to ensure a 100% argon, oxygen free environment inside of the closed welding head which helps to keep the welds clean and free from defects like sugaring. Closed heads work really well in tight spaces as well since they take less radial clearance than most open welding heads they can often fit where an open orbital welding head will not. Lastly, closed orbital welding heads work best on very small tubing with our Axxair microfit weld heads, especially our newest SAMX25 which is a very small but still water-cooled closed orbital welding head giving you excellent duty cycle while also remaining compact enough to fit in tigh spaces and weld tiny tubes.

Open Orbital Welding Heads Overview

Simply put, if you are welding tube or pipe and the wall thickness is much over .120" wall more often than not we are going to recommend you switch to an open head with a wire feed. Sometimes on "large" OD tubing say 6in or more it may better suit the application to use an open head even if you are not adding wire and only fusion welding simply because the "large" closed orbital welding heads can be heavy and hard to fit in some spaces. But in general if you are welding tubes or pipe more than .120" wall we should more often than not be looking at an open head. The open head also "opens" up some added capabilities for us. With the open orbital welding head design we can now add a wire feeder with OSC/AVC meaning we will have oscillation and torch height control (depending on the weldhead model).

More often than not, we are going to recommend our Magnatech D-Head orbital welding weld head for open head, wire-fed applications. The D-Head has an incredible pipe OD size range, welding pipes from 3/4" - 14" OD. This versatility is unheard of in orbital welding and really sets the D-head apart in terms of the value you get from a single weld head as many other OEMs would require several weld heads to achieve that pipe size range. We also really like the user-friendly orbital welding power supply options for the D-Head, the 515 and 516 Magnatech power supplies. These power supplies feature an easy to use interface, feature auto weld schedule generation. Auto weld schedule generation is very common on fusion welding power supplies but less so for wire-fed applications because it is much harder to generate weld schedules for wire-fed orbital welding applications. With so many welding parameters to program and adjust if your orbital welding power supply does not feature auto weld schedule generation you can find yourself spending many hours programming and making adjustments.

Conclusion

In general closed welding heads are simpler to setup and operate and will weld perfect x-ray quality welds so long as the application does not require filler wire to be added. We usually will recommend closed orbital welding heads for welding tubes and pipes from 6" and down .120" wall and thinner although there are exceptions to this rule of thumb where we may recommend an open head it just depends on the application and what you are trying to accomplish with the orbital welding operation. That's why it is always a good idea to give us a call and discuss your application with an expert so we can make sure you have the proper equipment, training and consumables for the job. GSI offers orbital welding machine rentals as well to get you started or if you have a specific job you only need a rental machine for.