How to Cut and Face Tubes for Orbital Welding

- George Ficken

- Aug 18, 2025

- 2 min read

In this article we wanted to walk through the proper way to cut and square tubing for orbital welding with GTAW (TIG) autogenous fusion welding. For this article we will be walking through the process with Axxair cutting saws and facing tools, which we are big fans of!

Tube or Pipe Cutting and Preparation

It all starts with the cut and the prep. The cut and prep are absolutely critical in achieving consistency and quality in orbital welding. Since today's orbital welding machines are program-based, the machine will make the same weld over and over again. This is good for consistency, however, it means that any variables that are introduced into the weld equation will have an impact on the weld. Since we spend time fine tuning our weld programs, we do not want to allow any changing tube fit-ups to interfere or cause problems. The best way to ensure a quality and consistent fitup is to cut with a very accurate saw that does not distort the tube and then square or "face" the tube ends so that you can have a gap-free butt joint.

The saws we recommend and love are the Axxair line of orbital cutting saws. Axxair has been manufacturing these saws for decades and not only do they last decades in harsh fab shop environments, they also cut extremely accurately (within .010" squareness) and do not distort the tube. They are able to do this firstly by implementing a concentric clamping system to allow even pressure distribution through the tube, keeping it round and avoiding distortion. Secondly, the saw only penetrates the blades just inside of the tube and then circulates around the tube to make the cut. This applies very little tool pressure onto the tube, unlike a traditional band saw that cuts at multiple points on the tube, the load is concentrated in just a small area.

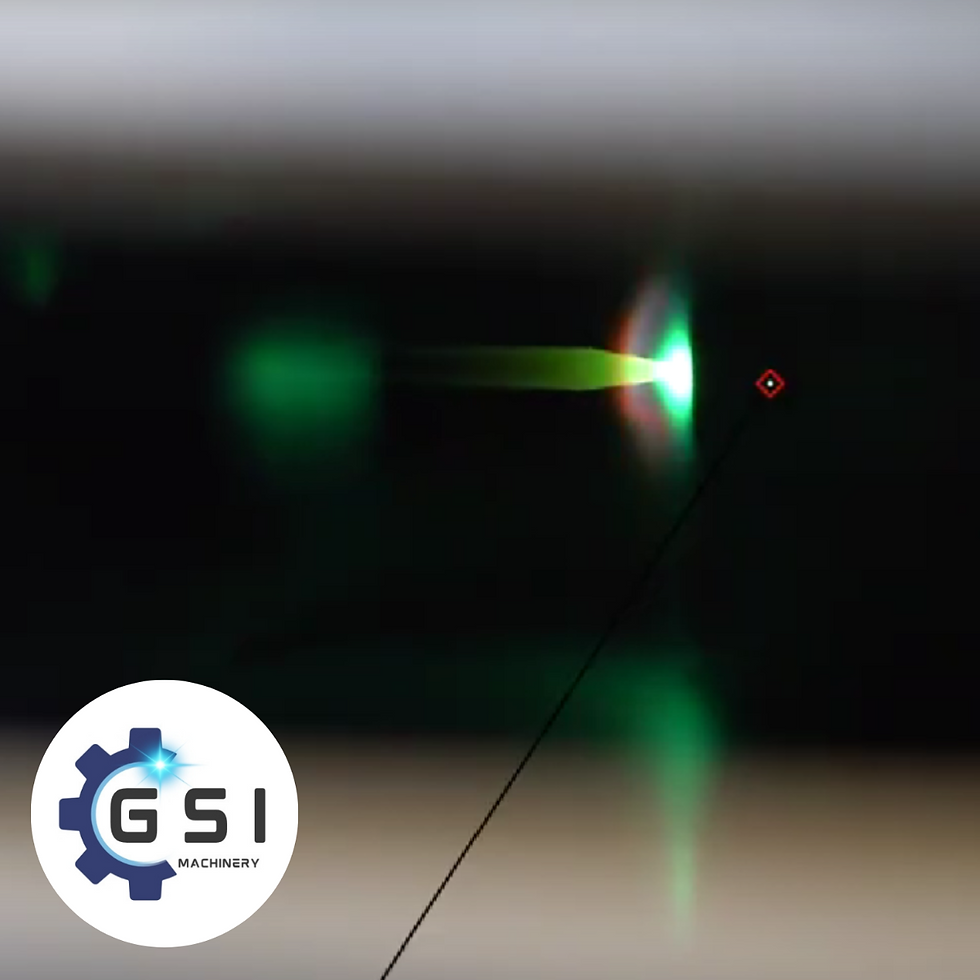

After cutting it is a good idea to put the tube into a facing tool to swuare the ends and create a nice machined-finish tube end. This gets rid of any potential burrs, tags or tooth marks from the blade causing butt joint gaps or misalignment. It also ensures no burrs add unwanted material to the weld puddle and or distort the arc path. Facing tools are relatively simple, just an electric motor (battery or plug-in) a gearbox and a small cutterhead with a carbide or high strength steel insert. GSI manufactures our own inserts to get you quality inserts at a competitive price, as we do saw blades.

Contact GSI Machinery to see a demonstration today. GSI offers rentals, sales, repairs and training on orbital cutting, facing and welding equipment right out of Houston, Texas.