Orbital Welding’s Impact on the Pharmaceutical Industry

- George Ficken

- Oct 17, 2023

- 2 min read

Updated: Oct 11, 2024

Orbital welding is a highly specialized welding technique employed in various industries, including the pharmaceutical sector. In this essay, we will explore the application of orbital welding in the pharmaceutical industry and the reasons for its widespread use.

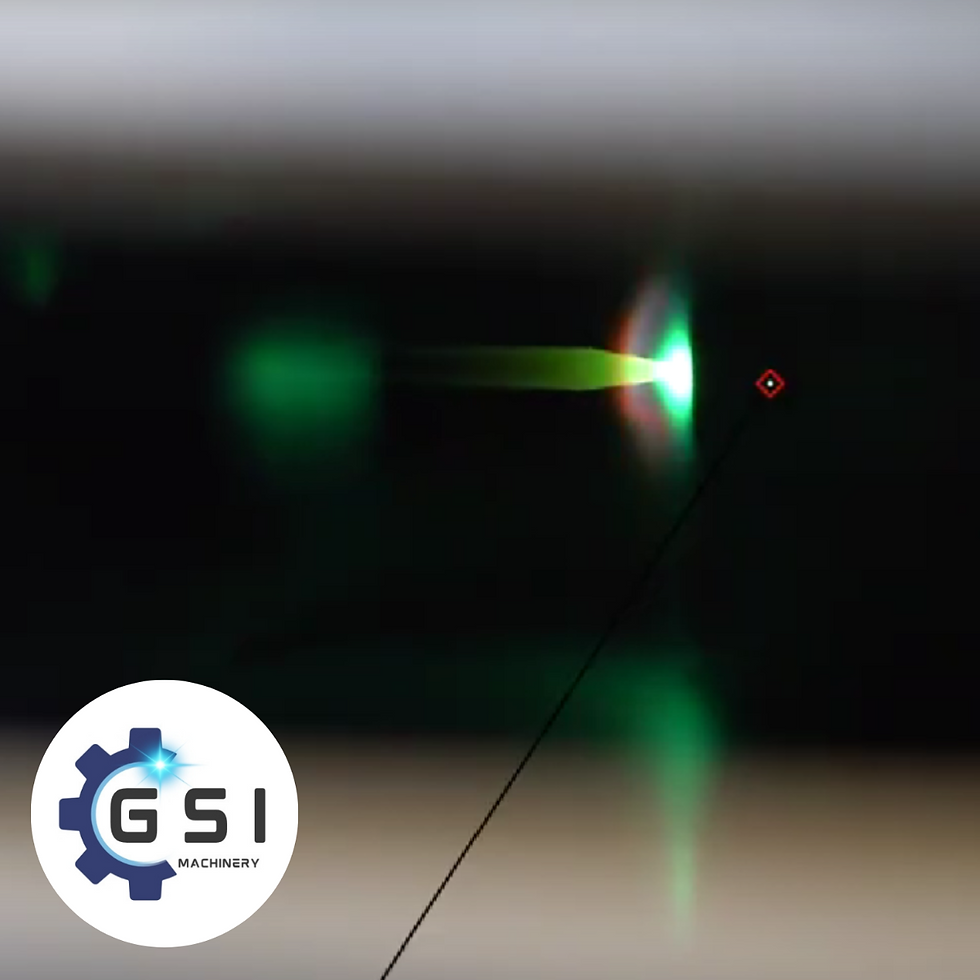

Introduction to Orbital Welding: Orbital welding is an automated welding process that utilizes a precision welding head that rotates around the workpiece. This method provides consistent and high-quality welds, making it ideal for industries with stringent quality and purity requirements, such as pharmaceuticals.

Pharmaceutical Industry's Quality Demands: The pharmaceutical industry demands the highest levels of product purity and sterility to ensure the safety and efficacy of medications. Any contamination in manufacturing processes can have severe consequences for patients.

Materials in Pharmaceutical Equipment: Pharmaceutical equipment is often made from high-purity stainless steel or other corrosion-resistant alloys. Orbital welding is well-suited for these materials, as it minimizes the risk of contamination and ensures weld integrity.

Hygienic and Sterile Welds: One of the primary applications of orbital welding in pharmaceuticals is in creating hygienic and sterile welds. These welds are essential in the construction of vessels, pipelines, and tubing systems that come into direct contact with pharmaceutical products.

Consistency and Precision: Orbital welding systems offer a high degree of consistency and precision. This is critical in pharmaceutical manufacturing to eliminate variability in weld quality, which can affect product quality and safety.

Welding in Controlled Environments: Pharmaceutical manufacturing often takes place in controlled environments with strict cleanliness protocols. Orbital welding minimizes human intervention and reduces the potential for contamination during welding operations.

Documentation and Compliance: In the pharmaceutical industry, strict documentation and compliance with regulatory standards are essential. Orbital welding systems can provide detailed records of welding parameters, which is crucial for regulatory compliance and traceability.

Conclusion: In conclusion, orbital welding plays a pivotal role in the pharmaceutical industry by ensuring the creation of high-quality, hygienic, and sterile welds. Its precision, consistency, and compliance with industry standards make it a preferred choice for critical applications in pharmaceutical manufacturing, where product purity and safety are of utmost importance. As the pharmaceutical sector continues to grow and evolve, orbital welding technology will likely remain an integral part of its manufacturing processes.