The Revolutionary Rotoweld 3.0: Transforming Pipe Welding with Automation

- George Ficken

- Nov 10, 2023

- 3 min read

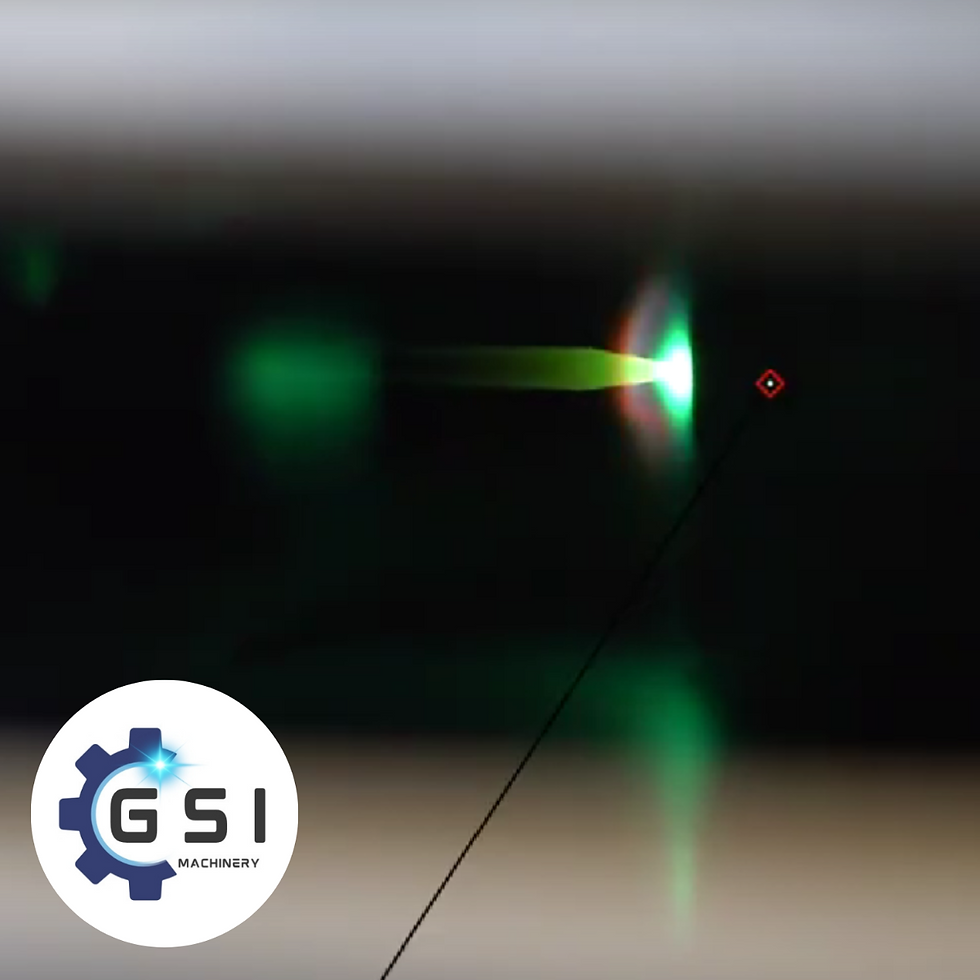

The Rotoweld 3.0 automated pipe welding machine stands at the forefront of technological innovation, reshaping the landscape of pipe welding with its cutting-edge features and unparalleled efficiency. This essay explores the myriad benefits that this revolutionary machine brings to the welding industry, ranging from increased productivity and cost-effectiveness to improved precision and safety.

Increased Productivity:

One of the standout benefits of the Rotoweld 3.0 is its remarkable impact on productivity. By automating the welding process, this machine dramatically reduces the time required for welding operations. It operates seamlessly, allowing for continuous welding without the need for frequent pauses or breaks. This not only accelerates project timelines but also ensures a consistent and high-quality weld, contributing to enhanced project efficiency.

Cost-Effectiveness:

In addition to boosting productivity, the Rotoweld 3.0 offers substantial cost savings for welding projects. The automated nature of the machine minimizes the need for manual labor, reducing labor costs and the potential for errors. Moreover, the precision of the automated welding process leads to decreased material waste, further optimizing costs. Over the long term, businesses utilizing the Rotoweld 3.0 can experience significant financial benefits, making it a wise investment for companies looking to improve their bottom line.

Precision and Consistency:

Precision is a hallmark of the Rotoweld 3.0, ensuring consistently high-quality welds. The machine's advanced technology allows for precise control over welding parameters, resulting in uniform welds with minimal variations. This level of consistency is challenging to achieve with manual welding, making the Rotoweld 3.0 particularly valuable for projects demanding precise specifications, such as those in the aerospace or energy sectors.

Versatility and Adaptability:

The Rotoweld 3.0's versatility is a key advantage, as it can accommodate a wide range of pipe sizes and materials. This adaptability makes the machine suitable for various industries, from oil and gas to construction. The ability to seamlessly transition between different welding requirements adds a layer of flexibility to projects, allowing for increased adaptability in dynamic work environments.

Safety Enhancement:

Safety is a paramount concern in any industrial setting, and the Rotoweld 3.0 addresses this with its automated design. By minimizing the need for manual intervention in the welding process, the risk of accidents and injuries is significantly reduced. Operators can control the machine from a safe distance, mitigating exposure to hazardous fumes and extreme temperatures. This focus on safety not only protects the well-being of workers but also enhances overall project reliability.

Remote Monitoring and Control:

The Rotoweld 3.0 is equipped with advanced monitoring and control features, enabling remote operation and supervision. This capability is invaluable for large-scale projects or situations where on-site presence may be challenging. Operators can monitor the welding process in real-time, make adjustments remotely, and troubleshoot issues without the need for physical presence, saving both time and resources.

Training and Skill Development:

While automation may raise concerns about job displacement, the Rotoweld 3.0 offers an alternative perspective. Rather than replacing skilled workers, it provides an opportunity for them to upskill and specialize in machine operation and maintenance. Training programs focused on the Rotoweld 3.0 can empower workers with new skills, ensuring a workforce that is adept at harnessing the benefits of automation, ultimately creating a more resilient and competitive industry.

In conclusion, the Rotoweld 3.0 automated pipe welding machine represents a paradigm shift in the welding industry. Its numerous benefits, including increased productivity, cost-effectiveness, precision, and safety enhancements, position it as a game-changer for various sectors. As technology continues to evolve, embracing automated solutions like the Rotoweld 3.0 not only propels industries forward but also fosters a more dynamic and skilled workforce, ushering in a new era of efficiency and excellence in pipe welding.

Reach out to GSI Machinery to learn more about the Rotoweld 3.0 automated pipe welding machine including demonstrations and sample welds.